Laser Surface Cleaning

Achieve Better Battery Pack Performance & Reliability in eMobility

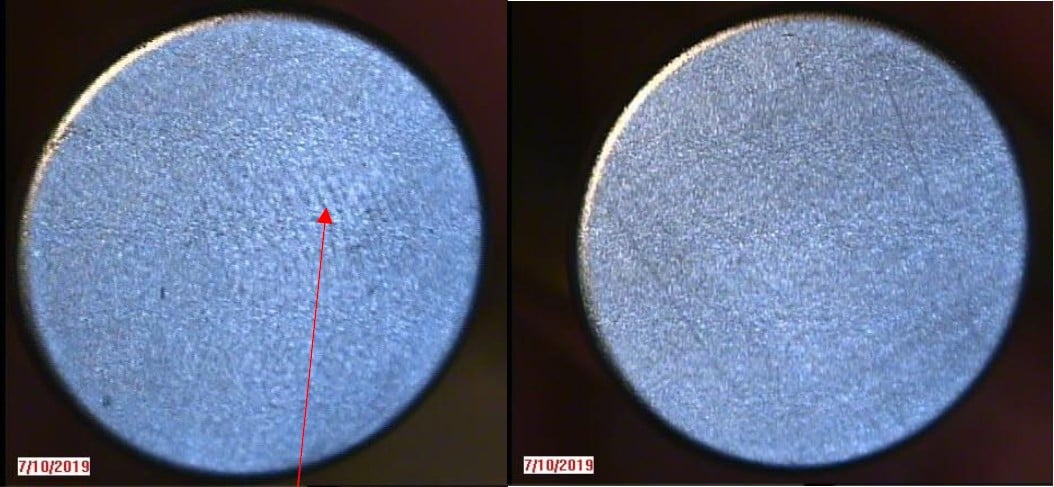

Research shows that laser cleaning battery connection areas prior to joining improves weld reliability and reduces battery pack manufacturing costs.

Get a copy of our latest paper outlining the challenges battery manufacturers are facing today and how laser cleaning is helping them to achieve better performance and reliability.